A friendly reminder that today is our last shipping date. Any orders after 12pm will not be processed and you probably won’t receive your items till the new year.

We hope you understand and have a great festive season.

#protectingyourelectronics #Christmas #LastShippingDate

Product Spotlight – Cho-Therm 1642 and Primer 1087 (277g Kit)

Todays #ProductSpotlight focuses in on Cho-Therm 1642 and Primer 1087 (277g Kit)!

Cho-Therm 1642 is a two-part thermally conductive sealant. Combining the features of Ceramics and silicone. This product doesn’t require water vapour to cure. The material has a mix ratio of 100:3 which is decided by their weight. Combining the two-part Cho-Therm 1642 with Primer 1087 allows for a permanent bond to be formed.

Cho-Therm 1642 & Primer 1087 (277g kit)

Features and Benefits:

- Thermally conductive

- Electrically insulating

- Easy to use

- Long working life

- Good for thick applications

#Chomerics #Adhesive #protectingyourelectronics

Product spotlights – End of 2024Product spotlightsProduct spotlights – End of 2024

Missed any of our #ProductSpotlights this year?

Don’t fret, we have you covered. Visit the webpage below to find all the products we have been raving about this year. From Adhesives to Yarn, we’ve aimed to provide you with a wide variety of products from our suppliers this year. With the last shipping date closing in fast for this year we want to thank all our suppliers for the products we are able to offer, to #protectyourelectronics.

Take a look at our collection here – https://www.hitek-ltd.co.uk/category/updates/product-spotlight/

#Chomerics #Henkel #Permabond #Shieldex #ABSTechnics #HITEK-nologySolutions #Orbel #Cortec

Last Shipping Date of 2024

With the festive season upon us, HITEK will be closing for the year on the 24th of December. That being said our last shipping date will be 20th December 2024. If you do plan to order from us then ideally do so before 11am so that your orders can be processed and shipped on that day. Any orders after 12pm will not be processed and you probably wont receive your items till the new year.

We hope you understand and have a great festive season.

#protectingyourelectronics #Christmas #LastShippingDate

Brand Spotlight – Shieldex

Todays #BrandSpotlight focuses on our partner for EMI Shielding fabrics and yarns, @Shieldex

With a broad range of products available, Shieldex offer products that aim to prevent EMI Interference. While we do offer yarns and fabrics online we also have the capability as their UK distributor to offer some of their shielded enclosure solutions.

Check out their brand page here to see exactly what they offer: https://www.hitek-ltd.co.uk/shop/shop-by-brand/shieldex/

Technical Tips – Surface Preparation For Epoxies, Acrylics and Silicones

Surface preparation is a critical aspect in the use of epoxy resins. In order to create an effective bond, the surface must be clean. Dirt, oil, moisture and weak oxide layers prohibit good adhesive bonding, and must be removed through proper surface preparation methods. Otherwise, the adhesive will bond to these boundary layers rather than to the substrate. Surface preparation enhances the quality and permanence of a bonded joint by performing one or more of the following functions:

- Removing contaminants

- Controlling absorbed water

- Controlling oxide formation

- Poisoning surface atoms that catalyse polymer breakdown

- Matching the substrate crystal structure to the adhesive molecular structure

Sufficiently clean surfaces can usually be obtained by thorough one of the following

- Surface degreasing with a solvent

- Wire brushing

- Sand blasting

This is usually adequate for most metals and plastics. Once the surface has been cleaned, precautions should be taken to eliminate contamination of the cleaned surface.

The following surface preparations have been recommended in the literature. Where appropriate, they are followed by a neutralising rinse, a water rinse and an oven dry.

Ferrous metals

Sand blasting with grease free sand or wire brushing has been found generally satisfactory for iron. In some cases

chemical cleaning solvents can be used

Non-Ferrous metals

Aluminium and aluminium alloys:

Degrease and dip for 10 minutes at 70°C in the following solution (parts by weight):

- 66 pbw Sodium dichromate

- 666 pbw 96 % sulphuric acid

- 1000 pbw Water

The solution should not be overheated, since at temperatures above 70°C there is a re-arrangement of the

surface of the aluminium, which leads to poor bonds. The sodium dichromate etch gives a controlled and

porous layer of aluminium oxide on the surface. If this film is exposed to air too long, the film will become too

thick and this will lead to poor adhesion. Therefore, material should be bonded within 2 hours after the

etching.

Copper and copper alloy

Etch for 1 to 2 minutes at room temperature in the following solution (parts by volume):

- 15 pbv 42% ferrite chloride

- 30 pbv concentrated nitric acid

- 197 pbv water

Gold

Degrease and roughen surface

Lead

Degrease and abrade with emery cloth

Nickel

Etch 5 seconds in concentrated HNO3.

Zinc and Zinc alloys

Degrease and abrade with emery cloth. Apply epoxy resin immediately. Material can also be etched by using

an etch solution (20 parts concentrated HCl/80 parts water) 2 to 4 minutes at room temperature.

Other Surfaces

Thermosetting Plastics

Clean the surface with a solvent, followed by a light sanding to remove surface contamination. This treatment has

been found satisfactory for diallyl phthalate, epoxy, phenolic, polyester, polyurethane, and urea-formaldehyde

resins.

For some plastics a plasma treatment can be used to obtain good adhesion. Specialised companies should be

contacted to receive detailed information.

Carbon

Degrease, abrade with fine emery cloth and degrease.

Ceramic

Degrease, abrade with carborundum/water slurry.

Glass

Solvent cleaning with trichloroethylene.

The degree to which substrates must be prepared depends upon several factors including the ultimate bond strength required, the degree of performance needed, the service environment, the amount of contamination on the substrate and the type of substrate.

For example, for plastics surface preparation can be more effective than for metals, as most are contaminated with either mould release or wax which must be removed prior to bonding.

In encapsulation applications, it is important that good bonding is obtained with the surface of the substrate of the housing. Bond strengths and bond performance depend greatly on the type of substrate which is in contact with the encapsulant. The main purpose of surface preparation is to ensure that adhesion develops in the joint between substrate and encapsulant, in order to minimise moisture absorption and to improve chemical resistance at this

interface.

Want an offline copy? Download it below!

Product Spotlight – Shieldex Nora Dell Fabric

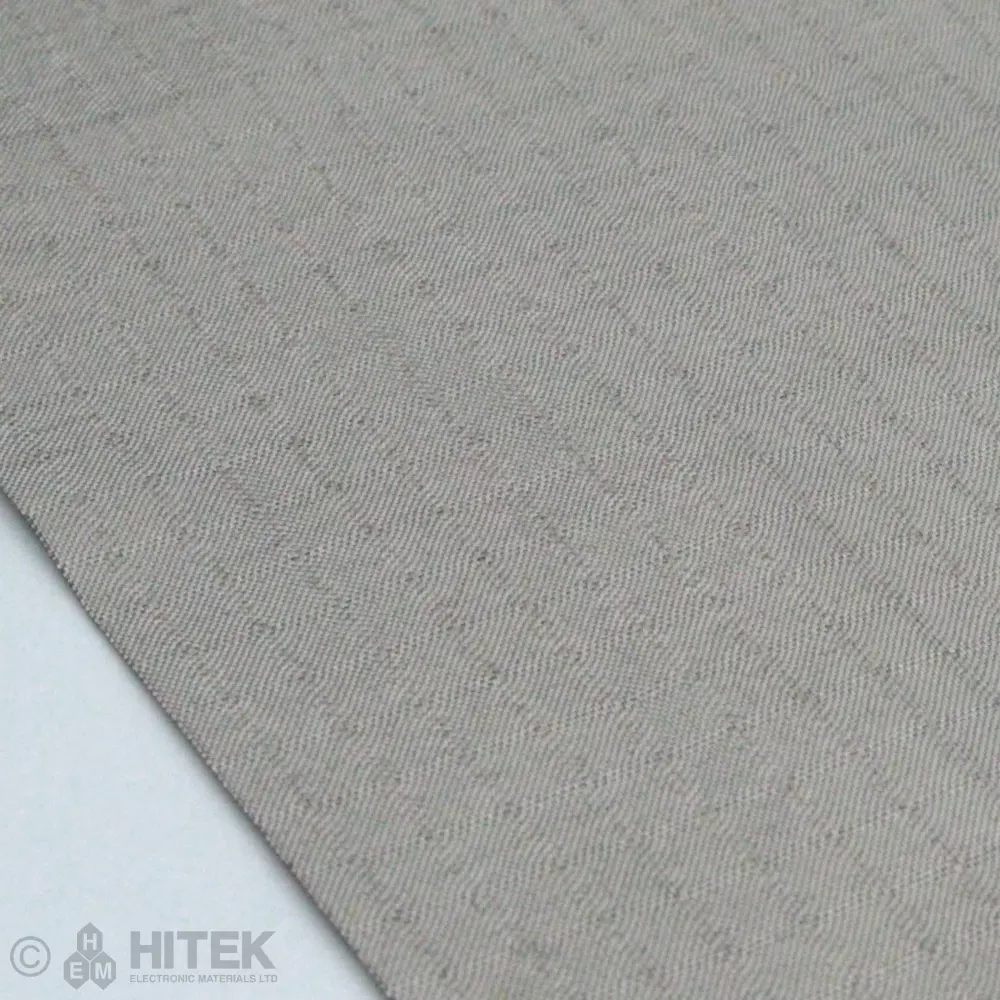

Today’s #ProductSpotlight is on @Shieldex Nora Dell.

A woven solution from Shieldex, this fabric offers a high level of thermal and electrical conductivity. Available as 500 x650mm or 1000x1300mm sizing this product provides shielding up to 56db in a 26-40 GHz frequency range. typically this product is used for most if not all technical situations that require high conductivity and shielding.

Shieldex Nora Dell Fabric

Features and benefits

- Ni/Cu/Ag plated polyamide fabric.

- Surface resistivity: average 0.009 ?/m2.

- Shielding effectiveness : Average up to 95 dB from 300 MHz to 10 GHz.

#Shieldex #Fabric #protectingyourelectronics

Best Seller – Tecan Shielding Can 4SFL-3020-10

Now that November has ended and Christmas season is upon us, its time to announce the #BesSeller. This month goes to @Tecans Shielding can 4SFL-3020-10!

Tecan Shielding Can 4PFL-3020-10 is a part of Tecan’s standard range of 4 sided cans with a plain-folded lid. This product comes in the dimensional size of 30mm x 20mm x10mm and is manufactured from 0.4mm copper. These shielded cans are complete by a bright tin plated finish.

Tecan Shielding Can 4SFL-3020-10

Features and Benefits:

- Tecan Shielding Can 4SFL-3020-10

- Tecan’s standard can range

- 4 sided can with spring-fingered lid

- 30mm x 20mm x 10mm

- Manufactured from 0.4mm copper

- Bright tin plated finish.

#Tecan #ShiedlingSolution #protectingyourelectronics

Product Spotlight – Bergquist Gap Pad TGP HC3000!

Today’s #ProductSpotlight focuses on @Henkel Bergquist Gap Pad TGP HC3000!

BERGQUIST GAP PAD TGP HC3000 is a gap filling material specifically designed for applications where components need a gentle touch. This soft and compliant material easily fills gaps and conforms to uneven surfaces, all while delivering impressive thermal performance (3.0 W/m-K).

BERGQUIST GAP PAD TGP HC3000

Part Number: GPHC3.0-0.040-02-0816

Features and Benefits:

- Thermal Conductivity: 3.0 W/m-K

- High-compliance, low compression stress

- Fiberglass reinforced for shear and tear resistance

#ChannelPartners #ThermalManagement #protectingyourelectronics

Product Spotlight – Cho-Foil CCJ 18-201-0050

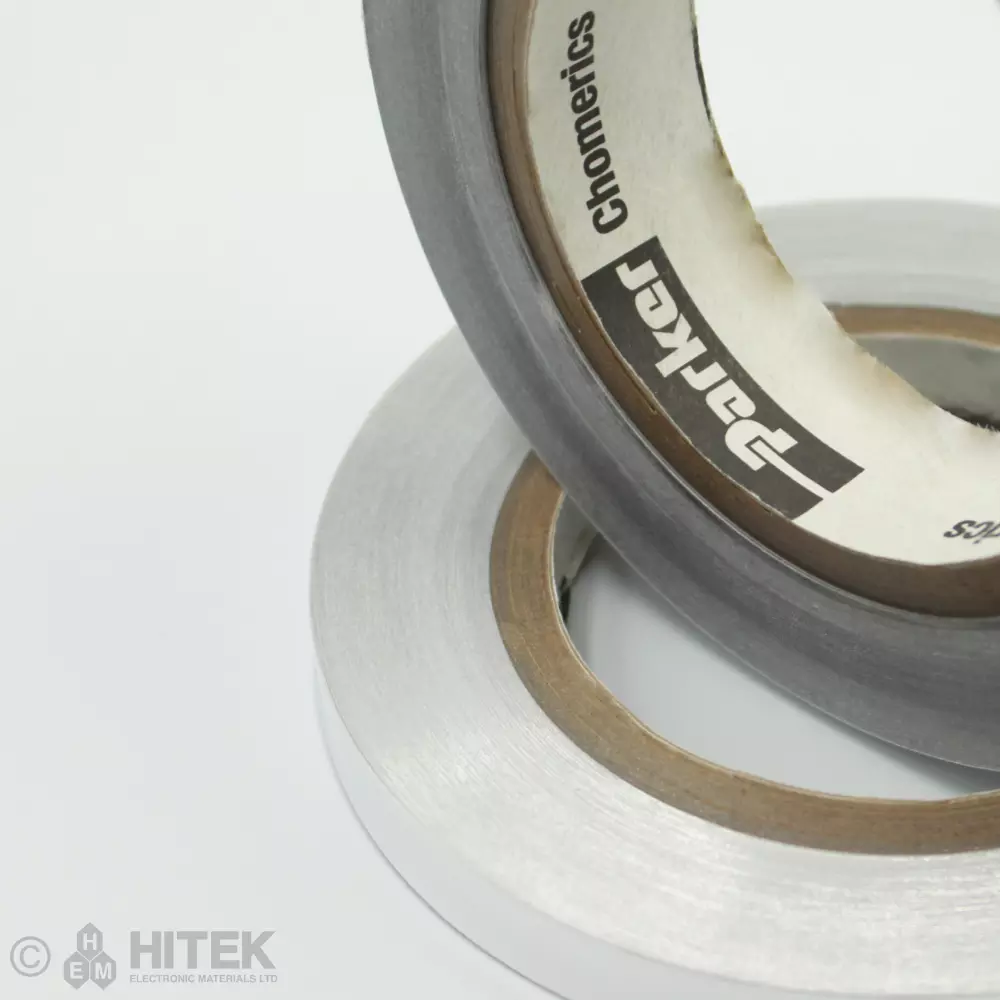

Today’s #ProductSpotlight focuses on @Parker Chomerics Cho-Foil CCJ 18-201-0050!

@Parker Chomerics’ CHO-FOIL® metal foil tapes provide an economical solution to applications requiring excellent electrical conductivity across substrates. These foil tapes can provide a low impedance connection between a braided cable shield and the metal connector back shell in moulded cables. Due to the highly conductive pressure sensitive acrylic adhesive (PSA), the tape can provide an effective shielded cable assembly without the need for soldering the tape to the braid

Cho-Foil CCJ

Part Number: 18-201-0050

Features and Benefits:

- Aluminium

- Available in 16.45m or 32.91m rolls lengths

- • Foil thickness 0.0508mm

- Supplied with single sided conductive acrylic pressure sensitive adhesive

- Temperature range from -40°C to +400°C

- Electrical resistance of <0.0016 ohms/cm²

- UL94 V-0 compliant

#Tapes #Thermalmanagement #protectingyourelectronics