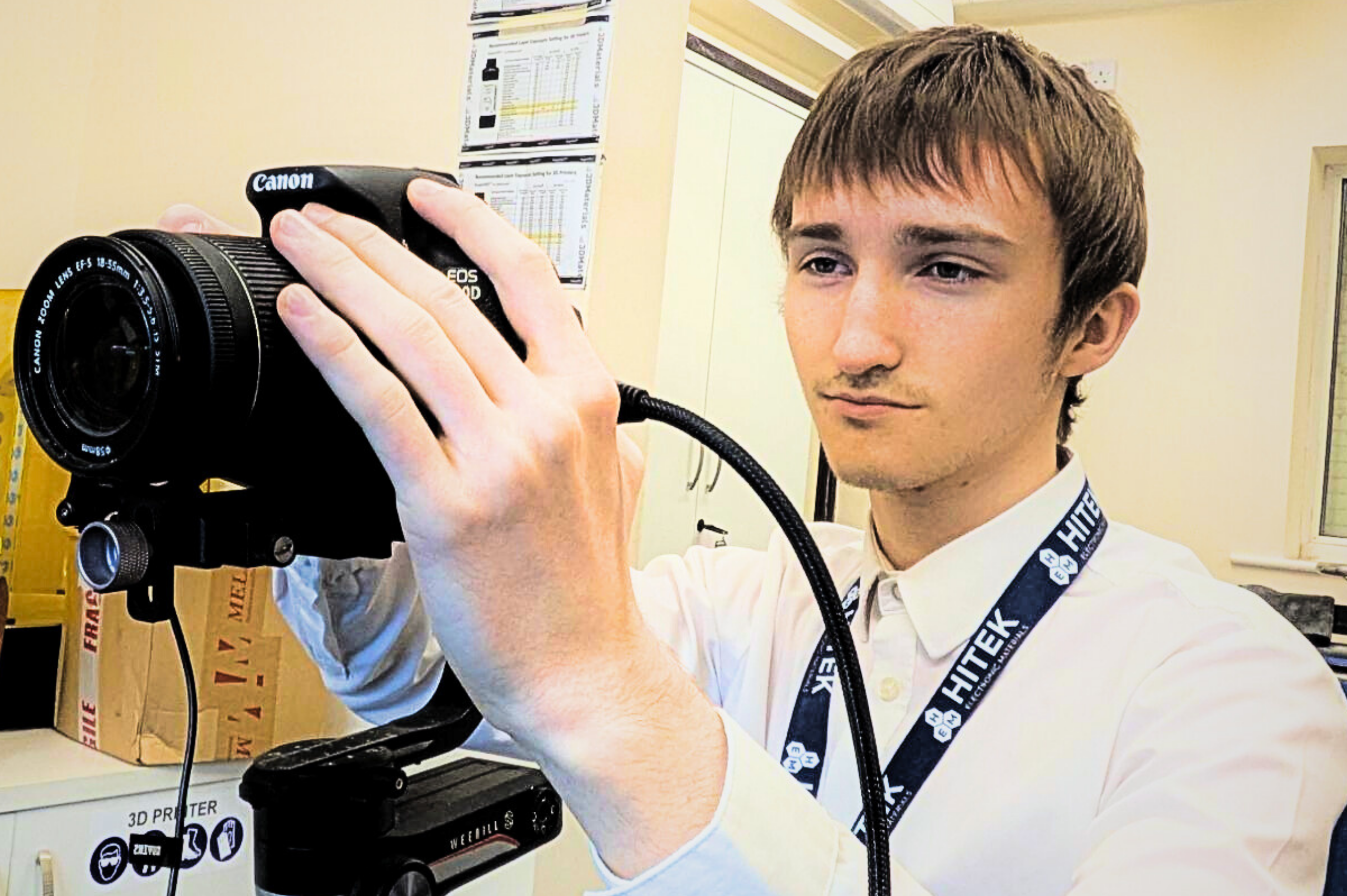

At HITEK, we know that technical expertise is only part of the story. What sets us apart is the people who bring that expertise to life – combining deep product knowledge with a real commitment to our customers. Our Technical Manager, David McAllister is a brilliant example of just that.

Solving Challenges Others Can’t

Customers tend to come to David when they’ve hit a wall – when something’s not working as expected, or they’re developing a product that needs robust protection for its electronics. It might be shielding against electromagnetic interference, withstanding environmental conditions, or absorbing microwaves. Often, it’s a combination.

His role isn’t simply about answering questions. It’s about interpreting the challenge, identifying potential risks, and matching the right materials to the task – all while ensuring compliance with evolving regulations like REACH and RoHS. A deep understanding of both the products and the customer’s requirements is essential.

The information he provides can have significant implications – particularly in sectors like aerospace, defence, and marine, where protecting sensitive electronics isn’t just about performance. It’s about safety. In some cases, lives depend on getting it right.

From Desk to Battlefield

One memorable project came from a customer with a damaged, unidentifiable radar-absorbing foam. Not only was a replacement sourced, but David also identified an environmental coating that, when applied, improved the performance of the absorber.

The solution was tested at the University of Sheffield and is now used on HM Forces Chinook helicopters. It’s an achievement to be proud of – but it’s also representative of how HITEK operates. That level of care, effort, and technical problem-solving is simply part of the day-to-day.

Driven by Curiosity, Backed by Data

David is known for being thorough, dedicated, and curious – qualities that have served him well throughout his career. His decisions are backed by hard data, safety sheets, and practical understanding, but equally by instinct and experience.

He doesn’t just provide a solution – he anticipates what might be coming next, helps customers understand their options, and gives them the confidence to move forward knowing they’re protected.

A Life Less Ordinary

Outside of his HITEK story, there’s a rich and surprising story. While serving in the RAF, he spent two decades as a mobile disco DJ – even hosting his own radio shows at the Waddington Air Show and RAF Stanbridge. His love for music and people led him to organise the UK’s biggest pop quiz for BBC Radio Lincolnshire’s Going for Gold appeal in 1997.

Over the years, he’s raised around £25,000–£30,000 for a wide range of charities, including the MS Society, Cancer Research, RNIB, Help the Aged, and many more. His ability to bring people together and make a difference stretches far beyond his day job.

Family, Football and Good Tunes

Today, he enjoys spending quality time with his family and is a proud Newcastle United fan – since 1967, no less – which he jokes has taught him patience! A music lover and sports enthusiast, he’s still driven by the same curiosity and dedication that define his work at HITEK.

The People Behind the Protection

He might not seek the spotlight, but his contribution to HITEK is hard to miss. From complex technical advice to collaborative customer support, David helps turn challenges into solutions – and brings a whole lot of character along the way!

It’s this blend of expertise and personality that makes HITEK what it is. Powered by people – and proud of it.

Check back next month to meet another fantastic member of our team!