Have you ever read a technical datasheet and questioned what Shelf, Pot and Working life means?

These terms appear frequently in the properties sections of a products TDS, and offer some vital information as to how long a product can be used for.

What is Shelf life?

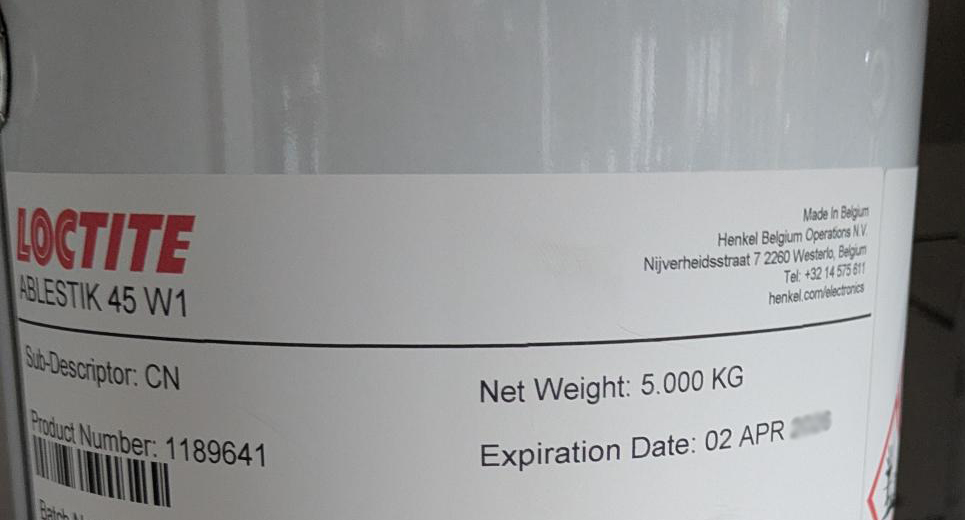

As it suggests, Shelf life is the length of time from the date of manufacture (or packaging) during which the material will be under warranty to behave according to the technical data sheet, assuming the storage conditions and correct application procedures have been met. This is usually found on the product label, which may either state an expiry date (the date when the shelf life runs out) or a manufactured date (in which case you have to find out the shelf life from a data sheet to calculate the expiry date).

Imagine buying something with a use by date from a store. How many times have you got home, put it in the fridge or freezer, left it longer than you thought you would then discover it two or three weeks after the use by date. Do you just throw it out? There are choices:

- Throw it out, accept that it is money wasted and take the hit.

- Defrost it, cook it, try it. Often the food is fine. This would be a self test.

- Take it back to the store, hope that the manager has enough good will to exchange it, but realise that he/she has no obligation to do this.

Materials do not become instantly ineffective at midnight on the day the use by or shelf life passes. Nevertheless, material suppliers must draw a line in the sand. with the benefit of expert formulation knowledge and extensive life testing, we know how long the products can be safely guaranteed. After the expiry date, the materials can be used, but at the complete risk of the user.

We help our customers by making sure we have very strict stock rotation on our premises, on a rigid FIFO basis, and with optimal storage conditions. We balance the needs of having stock for next day delivery against the loss of shelf life whilst sitting on our shelves. HITEK deliver with as much remaining shelf life as we can.

What is Pot Life?

Pot life is a data point defined as the amount of time it takes for an initial mixed viscosity to double. Timings start from the moment the product is mixed and is generally measured at room temperature. Adhesives which require elevated temperatures to cure, or exhibit high thixotropy, may need to be treated differently. Many of these thermoset materials will generate heat (exotherm) during the cure process, and so the temperature will increase during curing, and since this exotherm is related to the mixed mass – the more you mix, the shorter the pot life.

What is Working Life?

Working life, is the amount of time a mixed material remains low enough in viscosity so that it can still be readily applied to a part or substrate of the application, with the appropriate accuracy and tolerance. Working life is application dependent. Size and shape of bond-line, geometry, orientation, and even dispensing methodology will all come into it. As such, there is no standard method of determining working life, except what it turns out to be for your project.

Pot life can act as a guide in figuring out your working life – but some practical experimentation will be useful. Working life is generally shorter than pot life. There are risks in using a material beyond its stated pot life, even if it is still thin enough to apply. If the cross linking has gone too far before application, then adhesion and other physical characteristics may be compromised.