Disaster struck just days before the big day — the Easter Bunny suffered an unexpected accident and lost an ear during final prep!

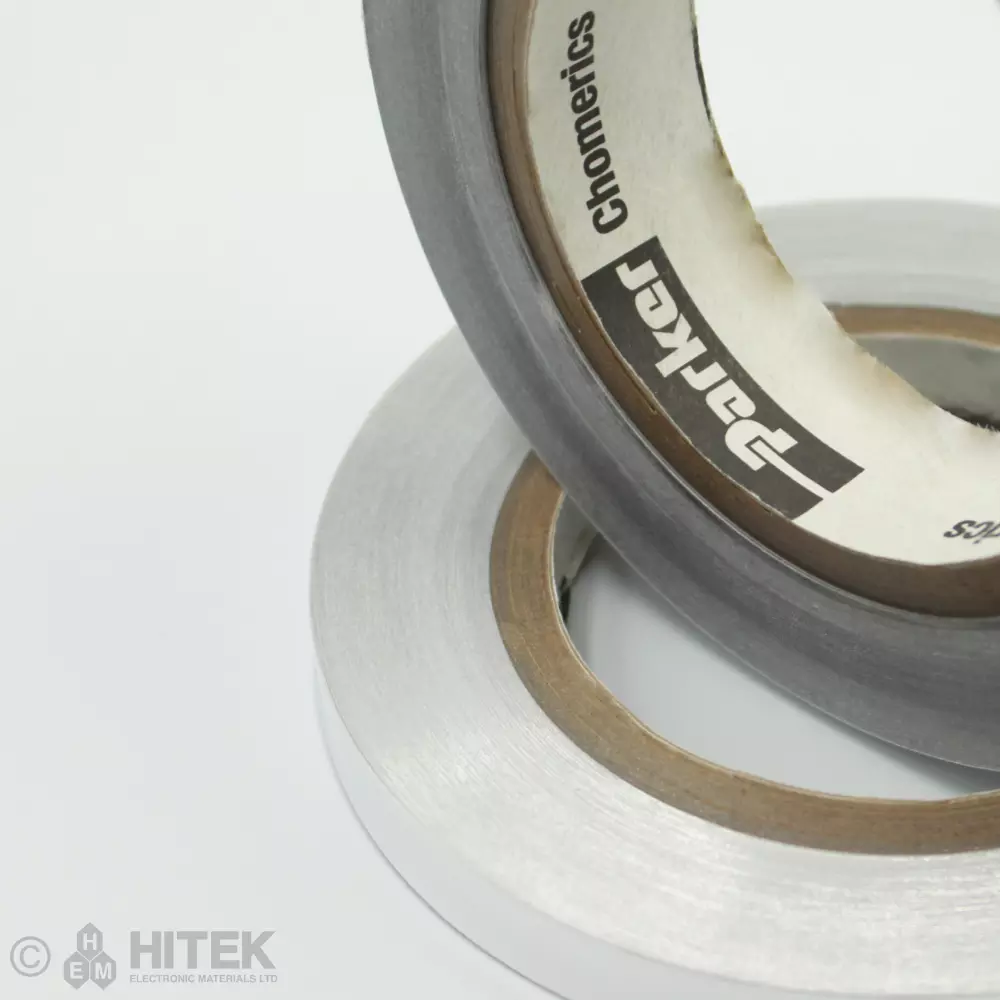

But panic didn’t last long. With our fast-acting team and trusty Permabond Engineering Adhesives 943 on hand, we had him back to his best in no time.

💡 Why Permabond 943?

This low odour, non-fogging, non-frosting adhesive was the perfect solution for a clean, invisible bond – no smudges, no sticky residue, and no delays.

✔️ Low odour = happier helpers

✔️ No fogging = perfect photo finish

✔️ Strong, reliable hold = one hoppy Bunny

Another seasonal save thanks to smart materials and even smarter applications.